-

Nickel & Cobalt Alloy

- Alloy C276 - UNS N10276

- Inconel 601® - UNS N06601

- Inconel 617 - UNS N06617

- Inconel 625®

- Inconel 718

- Inconel X750®

- Inconel 600® - UNS N06600

- Incoloy® 800 Advanced Nickel Alloy

- Incoloy 825®

- Hastelloy X® - UNS N06002

- Hastelloy B-2® Nickel Alloy

- Hastelloy C276® - UNS N10276

- Hastelloy C22 - UNS N06022

- Haynes 25™ Alloy L605

- Haynes 188™ - UNS R30188

- Monel R405® - UNS N04405

- Invar 36® Superalloy

- Kovar® - UNS K94610

- Alloy Al6XN® - UNS N08367

- Jethete® M152

- Alloy A286® Austenitic Stainless Steel

- Alloy 330® - UNS N08330

- Monel 400® - UNS N04400

- Nickel 201

- Nickel 200 - UNS N02200

- 940L

- 253MA

- Wrought Low Alloy

- Nickel & Cobalt Alloy

021-61730680

021-61730680 sales@jiangsusteel.com

sales@jiangsusteel.com

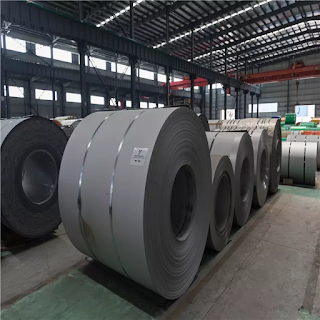

L 605 Nickel & Cobalt Alloy Bar/Tubing/Sheet/coil

JIANGSU STEEL GROUP Inquiries :

1. Commodity:L 605 Nickel & Cobalt Alloy Bar/Tubing/Sheet/coil

2. Grade:L 605

3. AMS SPEC:AMS 5537, 5759, 5796

4. Certification:ISO

8. Length: As your requests

10.Delievery Time:According to your size and quantity or as require

11.Payment term:TT/ LC

12. ApplicationŁşIndustry,building materials,machinery,construction.

Material Data Sheet

Alloy L605 is a non-magneticcobalt-based superalloy. It is the strongest of the formable cobalt alloys,useful for continuous service up to 1800ˇăF and maintaining useful strength upto 2150ˇăF. L605 maintains good oxidation resistance up to 1900ˇă Fand has a unique ability to resist corrosion in very severe environments. L605Is also highly resistant to hydrochloric acid, nitric acid, and wet chlorine(subject to the need for exercising care in its selection at certainconcentrations and temperatures).

Because of long and widespread use, alloyL05 has been the subject of many investigations to determine its propertiesover a wide range of conditions, thus making it an unusually well-characterizedmaterial. Alloy L605 is also known as alloy 25.

When exposed for prolonged periods atintermediate temperatures, alloy L-605 exhibits a loss of room temperatureductility in much the same fashion as other superalloys, such as Hast-X or Inco625.

Alloy L605 is welded using gas tungstenarc, gas metal arc, shielded metal arc, electron beam, and resistance welding.Submerged arc welding is not recommended. Use good joint fit-up, minimumrestraint, low inter-pass temperature, and cool rapidly after welding. Formaximum ductility fabricated components should be annealed 2150-2250ˇăF,followed by a rapid cool.